Catalytic Converter Basics

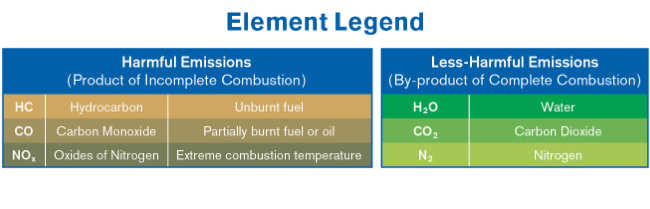

The catalytic converter is designed to convert harmful emissions produced by an internal combustion engine to less-harmful elements: H2O (water), CO2 (carbon dioxide) and N2 (nitrogen).

To perform this conversion, the catalytic converter works with a vehicle's PCM (Powertrain Control Module) and other emissions control devices. The OBDII (On-Board Diagnostics Version 2) system monitors the emissions control devices and provides feedback on their operating conditions. As the EPA (Environmental Protection Agency) updates emissions standards, the OBDII systems for newer vehicle models are calibrated by engineers to be more sensitive to fluctuations in emissions performance.

Catalytic converters can only function efficiently if the engine is operating properly and the exhaust system is leak-free. Malfunctioning sensors or actuators, damaged engine components, too-rich or too-lean fuel mixtures, and inconsistencies between engine cylinders may lead to converter efficiency issues and possibly damage the catalyst.

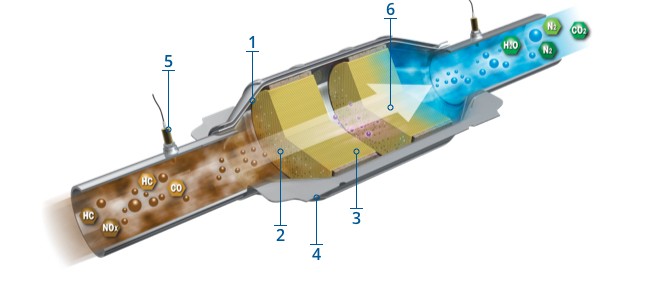

Anatomy of a Catalytic Converter

1 - Stainless Steel Body

Engineered for long life and durability. The ribbed body minimizes expansion and distortion, as well as forming pockets that protect the cushioning mat from direct exposure to exhaust gases.

2 - Monolithic Free-Flowing Substrate

The substrates are the backbone of the converter. This is where the proprietary mix of precious metals and the washcoat allow the conversion process to take place. Coatings are engineered for high temperature durability and optimal catalytic activity, as well as OBD system compatibility. Converters are available in single- or multiple-substrate designs.

3 - Catalyst Cushioning Mat

The mat cushions the converter substrate, holding the ceramic catalyst in proper alignment and accommodating for thermal expansion of the body.

4 - Head Shields to Match OE

Protects the vehicle’s undercarriage from heat created by the chemical reactions in the converter.

5 - O2 (Oxygen) Sensor Ports

Another vital part of an emissions control system, these sensors are placed before and after the catalytic converter on an OBDII vehicle. They are designed to monitor the O2 levels in the exhaust gas and are also used to evaluate the status of the converter. This information along with data provided by the mass air flow, MAP (manifold absolute pressure) and engine sensors, allow the PCM to adjust fuel controls.

6 - Precious Metals/Catalysts

The precious metals introduced onto the substrate serve as catalysts that chemically process raw exhaust gases. Those most commonly used are platinum (Pt), palladium (Pd) and rhodium (Rh).

Learn more about quality exhaust parts, find the right car part, or find a local repair shop today.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.